Selection and Use of Gloves in the Laboratory

Key Concepts to Remember

Understand the toxicity and hazards of the materials you work with

- Consult the MSDS for each chemical/product you work with for additional information on glove selection.

- Use special care handling chemicals with high acute toxicity and those with significant chronic effects (known carcinogens etc.).

- Contact EHS with questions on engineering controls and glove selection before handling dangerous materials.

All Gloves are Permeable

- Permeation is dependent on many factors including the material handled, extent and length of contact.

- Glove composition, thickness, fatigue and conditions of use also factor into glove effectiveness.

There is no such thing as an "ideal" chemically resistant glove

- Some gloves may offer superior protection but limit dexterity and tactile sensitivity or be prone to tears or punctures.

- Sometimes the best glove is actually two gloves worn together.

- Reusable gloves (ex. Nitrile, Neoprene, Butyl or Viton) can be worn over flexible laminate gloves to combine the advantages of both.

Consult the manufacturers chemical resistance guide

Below you will find links to glove compatibility data from companies that may supply gloves to Dartmouth College. Chemical Resistance varies according to manufacturer.

- In most cases the information provided includes degradation (a measure of the gloves tendency to swell, discolor or otherwise change due to chemical contact) and permeation.

- Permeation describes how some chemicals can pass through a glove on a molecular level. Chemicals can oftentimes permeate gloves without causing visible change.

- Breakthrough is the time lapsed between first contact outside the glove and detection inside.

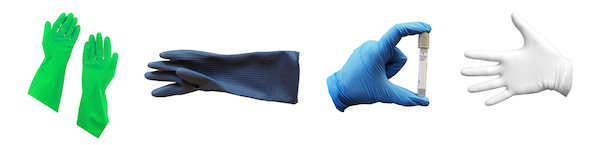

Understand the difference between reusable and disposable gloves

- Disposable gloves are thin single use gloves generally 4 - 8 mils thick compared to reusable gloves which are 18 - 28 mils thick (1 mil = 1/1000 inch).

- Disposable gloves are not suitable for handling aggressive or highly hazardous chemicals and should never be re-used.

- Disposable gloves can provide barrier protection where contact with chemicals is not likely.

- Whenever a disposable glove comes in contact with hazardous chemicals it should be removed followed by thorough hand washing and new gloves for continued work. Bag contaminated gloves for disposal as hazardous waste.

Care of reusable gloves

In the lab most chemical handling does not require immersion or extensive/prolonged contact. As a result it is normally not necessary to replace heavy-duty gloves after each use.

- Before removing reusable gloves, thoroughly rinse them off and then allow to air dry.

- Inspect reusable gloves before each use for discoloration, cracking at flexion points or damage (punctures or pin holes) - discard if discovered.

- If you suspect they have become contaminated bag them for disposal as hazardous waste.

Glove Materials

- Viton TM - Excellent resistance to chlorinated and aromatic organic solvents - Expensive

- Butyl - Good resistance to aldehydes, ketones and esters - Expensive

- Nitrile - Wide range of applications with puncture and abrasion resistant.

- Neoprene - Wide range of resistance to acids, caustics, and alcohols.

- PVC - Resists acids and caustics but not organic solvents.

- Natural Rubber/Latex - Minimal chemical resistance, often combined with other materials for a broad range of applications. Latex allergies limit widespread use.

- Flexible Laminates - North's Silver Shield/4H ® glove is a five layer laminate material that offers the best chemical resistance in most cases. It is best used as an inner liner under re-usable gloves to maintain dexterity and tactile sensitivity when handling extremely hazardous materials.